Standard O-Ring roller conveyor chain | o ring conveyor belts and chain | o ring chain assembly tool

- group name

- O-Ring Chain

- Min Order

- 100 meter

- brand name

- ZMIE Chain Manufacturer

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C

- update time

- Tue, 30 Dec 2025 03:07:37 GMT

Paramtents

Material: alloy steel/Stainless steel

Heat Treatment: Through hardening

Color: Natural

Shipping: Support Sea freight.Express.Land freight.

Packging & Delivery

-

Min Order100 meter

Briefing

Detailed

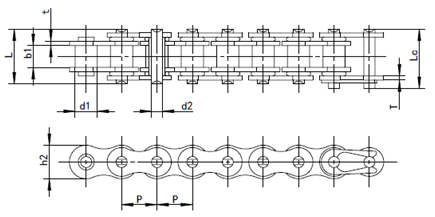

ZMIE Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness |

Ultiate tensile strength | Weight per meter | |

P | d1 max | b1 min | d2 max | L max |

Lc max | h2 max | T max | Q min | q | |

mm | mm | mm | mm | mm | mm | m | mm | KN | kg/m | |

40RO | 12.70 | 7.94 | 7.85 | 3.98 | 19.80 | 21.80 | 12.00 | 1.50 | 16.2 | 0.67 |

50RO | 15.875 | 10.16 | 9.40 | 5.09 | 23.50 | 25.70 | 15.00 | 2.00 | 25.0 | 1.19 |

60RO | 19.05 | 11.91 | 12.58 | 5.94 | 28.80 | 31.50 | 17.80 | 2.40 | 35.3 | 1.62 |

80RO | 25.40 | 15.88 | 15.88 | 7.94 | 40.10 | 43.00 | 23.40 | 3.20 | 57.8 | 2.70 |

08BRO | 12.70 | 8.51 | 7.75 | 4.45 | 19.60 | 21.60 | 11.80 | 1.50 | 17.8 | 0.74 |

10BRO | 15.875 | 10.16 | 9.65 | 5.08 | 23.20 | 25.50 | 14.70 | 1.70 | 22.2 | 1.00 |

12BRO | 19.05 | 12.07 | 11.68 | 5.72 | 28.60 | 31.30 | 16.10 | 1.80 | 28.9 | 1.30 |

16BRO | 25.40 | 15.88 | 17.02 | 8.28 | 39.80 | 42.80 | 21.00 | 4.0/3.2 | 60.0 | 2.90 |

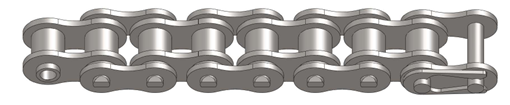

Both standard roller chain and o-ring roller chain are manufactured to ANSI B29.1 chain standards. This means both style roller chains are manufactured to set dimensions, which allows both styles to run on the same sprockets. The main difference is that o-ring roller chain uses an o-ring between the inner and outer plates, whereas standard chain is open without any seal. O-ring chains were originally developed as drive chains for motorcycles, but the technology is also used in standard industrial chains. A vacuum process is used to apply initial lubricant to the chain bearings, which are then sealed with an O-ring. This type of lubrication in combination with a seal means that these chains require no further lubrication throughout their entire service life, so they can be categorised as “low-maintenance”. O-ring chain has been tested and results have shown that O-ring chain can last up to 10 times longer than standard roller chain. The O-ring chain is named for the rubber O-rings built into the space between the outside link plate and the inside roller link plates. O-rings are included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside of the pin and bushing wear areas. Further, the rubber O-rings prevent dirt and other contaminants from entering the inside of the chain linkages, where such particles would otherwise cause significant wear. This O-Ring roller chain has heat treated & shot peened components that greatly extend the working life and strength of the chain.