Short pitch stainless steel roller chain | Short pitch roller chain | High temperature chain | Triplex roller chain

- group name

- Short Pitch Stainless Steel Roller Chain

- Min Order

- 100 meter

- brand name

- ZMIE Chain Manufacturer

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C

- update time

- Tue, 30 Dec 2025 01:30:24 GMT

Paramtents

Material: Stainless Steel

Heat Treatment: Through Hardening

Color: Zincplated, Nickel Plated, Black Finished

Shipping: Support Sea freight, Express, Land freight.

Chain Type: Simplex/Duplex/Triplex

Packging & Delivery

-

Min Order100 meter

Briefing

Stainless steel roller chain is the most common and widely used corrosion resistant roller chain in the world.

Detailed

Short pitch stainless steel roller chain | Short pitch roller chain | High temperature chain | Triplex roller chain

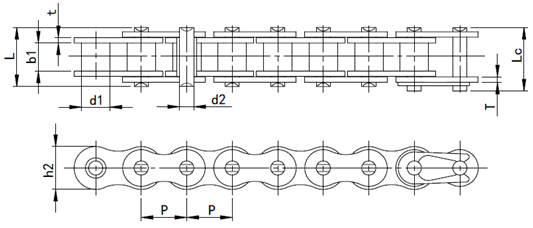

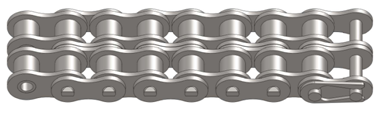

Simplex Chain

ZMIE Chain No. |

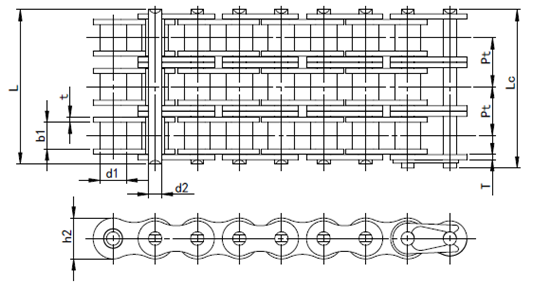

Pitch | Roller Diameter | Width Between Inner Plates | Pin Diameter | Pin Length | Inner Plate Depth | Plate Thickness | Ultimate Tensile Strength | Weight Per Meter |

||

P | d1 max | b1 min | d2 max | L max | Lc max |

h2 max | T max | Q min | q | ||

mm | mm | mm | mm | mm | mm | mm | mm | KN | kg/m | ||

04CSS-1 | 25SS-1 | 6.35 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | 2.10 | 0.15 |

06CSS-1 | 35SS-1 | 9.525 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | 4.74 | 0.33 |

085SS-1 | 41SS-1 | 12.70 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | 4.00 | 0.41 |

08ASS-1 | 40SS-1 | 12.70 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 8.46 | 0.62 |

10ASS-1 | 50SS-1 | 15.875 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | 13.32 | 1.02 |

12ASS-1 | 60SS-1 | 19.05 | 11.91 | 12.57 | 5.94 | 2.5.90 | 27.70 | 18.00 | 2.42 | 19.08 | 1.50 |

16ASS-1 | 80SS-1 | 25.40 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | 34.20 | 2.60 |

20ASS-1 | 100SS-1 | 31.75 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | 53.10 | 3.91 |

24ASS-1 | 120SS-1 | 38.10 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | 76.20 | 5.62 |

28ASS-1 | 140SS-1 | 44.45 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | 103.44 | 7.50 |

32ASS-1 | 160SS-1 | 50.80 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | 136.08 | 10.10 |

36ASS-1 | 180SS-1 | 57.15 | 35.71 | 35.48 | 17.46 | 72.80 | 78.60 | 53.60 | 7.20 | 168.12 | 13.45 |

40ASS-1 | 200SS-1 | 63.50 | 39.68 | 37.85 | 19.85 | 80.30 | 87.20 | 60.00 | 8.00 | 212.28 | 16.15 |

48ASS-1 | 240SS-1 | 76.20 | 47.63 | 47.35 | 23.81 | 95.50 | 103.00 | 72.39 | 9.50 | 306.18 | 23.20 |

04BSS-1 | 6.00 | 4.00 | 2.80 | 1.85 | 6.80 | 7.80 | 5.00 | 0.60 | 2.10 | 0.11 | |

05BSS-1 | 8.00 | 5.00 | 3.00 | 2.31 | 8.20 | 8.90 | 7.10 | 0.80 | 3.00 | 0.20 | |

06BSS-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | 5.40 | 0.41 | |

08BSS-1 | 12.70 | 8.51 | 7.75 | 4.45 | 16.70 | 18.20 | 11.80 | 1.60 | 10.80 | 0.69 | |

10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.50 | 20.90 | 14.70 | 1.70 | 13.44 | 0.93 | |

12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22.50 | 24.20 | 16.00 | 1.85 | 17.40 | 1.15 | |

16BSS-1 | 25.40 | 15.88 | 17.20 | 8.28 | 36.10 | 37.40 | 21.00 | 4.15/3.1 | 36.00 | 2.71 | |

20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 41.30 | 45.00 | 26.40 | 4.5/3.5 | 57.00 | 3.70 | |

24BSS-1 | 38.10 | 25.40 | 25.40 | 14.63 | 53.40 | 57.80 | 33.20 | 6.0/4.8 | 96.00 | 7.10 | |

28BSS-1 | 44.45 | 27.94 | 30.99 | 15.90 | 65.10 | 69.50 | 36.70 | 7.5/6.0 | 120.00 | 8.50 | |

32BSS-1 | 50.80 | 29.21 | 30.99 | 17.81 | 66.00 | 71.00 | 42.00 | 7.0/6.0 | 150.00 | 10.25 | |

40BSS-1 | 63.50 | 39.37 | 38.10 | 22.89 | 82.20 | 89.20 | 52.96 | 8.5/8.0 | 213.00 | 16.35 | |

48BSS-1 | 76.20 | 45.72 | 48.26 | 29.24 | 99.10 | 107.00 | 63.80 | 12.0/10.0 | 336.00 | 25.00 | |

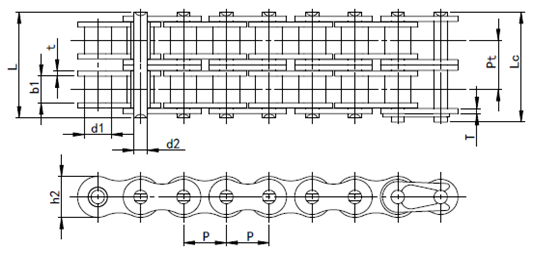

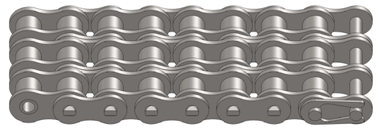

Duplex Chain

ZMIE Chain No. | Pitch | Roller Diameter | Width Between Inner Plates | Pin Diameter | Pin Length | Inner Plate Depth | Plate Thickness | Transverse Pintch | Ultimate Tensile Strength | Weight Per Meter | ||

P | d1 max | b1 min | d2 max | L max | Lc max | h2 max | T max | Pt | Q min | q |

||

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | kg/m |

||

04CSS-2 | 25SS-2 | 6.35 | 3.30 | 3.18 | 2.31 | 14.50 | 15.00 | 6.00 | 0.80 | 6.40 | 4.20 | 0.28 |

06CSS-2 | 35SS-2 | 9.525 | 5.08 | 4.77 | 3.58 | 22.50 | 23.30 | 9.00 | 1.30 | 10.13 | 9.48 | 0.63 |

085SS-2 | 41SS-2 | 12.70 | 7.77 | 6.25 | 3.58 | 25.70 | 26.90 | 9.91 | 1.30 | 11.95 | 8.00 | 0.81 |

08ASS-2 | 40SS-2 | 12.70 | 7.95 | 7.85 | 3.96 | 31.00 | 32.20 | 12.00 | 1.50 | 14.38 | 16.92 | 1.12 |

10ASS-2 | 50SS-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.90 | 40.40 | 15.09 | 2.03 | 18.11 | 26.46 | 2.00 |

12ASS-2 | 60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.80 | 50.50 | 18.00 | 2.42 | 22.78 | 38.16 | 2.92 |

16ASS-2 | 80SS-2 | 25.40 | 15.88 | 15.75 | 7.92 | 62.70 | 64.30 | 24.00 | 3.25 | 29.29 | 68.04 | 5.15 |

20ASS-2 | 100SS-2 | 31.75 | 19.05 | 18.90 | 9.53 | 76.00 | 80.50 | 30.00 | 4.00 | 35.76 | 106.20 | 7.80 |

24ASS-2 | 120SS-2 | 38.10 | 22.23 | 25.22 | 11.10 | 95.80 | 99.70 | 35.70 | 4.80 | 45.44 | 152.40 | 11.70 |

28ASS-2 | 140SS-2 | 44.45 | 25.40 | 25.22 | 12.70 | 103.30 | 107.90 | 41.00 | 5.60 | 48.87 | 206.88 | 15.14 |

32ASS-2 | 160SS-2 | 50.80 | 28.58 | 31.55 | 14.27 | 123.30 | 128.10 | 47.80 | 6.40 | 58.55 | 272.16 | 20.14 |

36ASS-2 | 180SS-2 | 57.15 | 35.71 | 35.48 | 17.46 | 138.60 | 144.40 | 53.60 | 7.20 | 65.84 | 336.30 | 29.22 |

40ASS-2 | 200SS-2 | 63.50 | 39.68 | 37.85 | 19.85 | 151.90 | 158.80 | 60.00 | 8.00 | 71.55 | 424.56 | 32.24 |

48ASS-2 | 240SS-2 | 76.20 | 47.63 | 47.35 | 23.81 | 183.40 | 190.80 | 72.39 | 9.50 | 87.83 | 612.36 | 45.23 |

05BSS-2 | 8.00 | 5.00 | 3.00 | 2.31 | 13.90 | 14.50 | 7.10 | 0.80 | 5.64 | 4.68 | 0.33 | |

06BSS-2 | 9.525 | 6.35 | 5.72 | 3.28 | 23.40 | 24.40 | 8.20 | 1.30 | 10.24 | 10.14 | 0.77 | |

08BSS-2 | 12.70 | 8.51 | 7.75 | 4.45 | 31.20 | 32.20 | 11.80 | 1.60 | 13.92 | 19.20 | 1.34 | |

10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 36.10 | 37.50 | 14.70 | 1.70 | 16.59 | 26.70 | 1.84 | |

12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 42.00 | 43.60 | 16.00 | 1.85 | 19.46 | 34.68 | 2.31 | |

16BSS-2 | 25.40 | 15.88 | 17.02 | 8.28 | 68.00 | 69.30 | 21.00 | 4.15/3.1 | 31.88 | 6.360 | 5.42 | |

20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.80 | 81.50 | 26.40 | 4.5/3.5 | 36.45 | 102.00 | 7.20 | |

24BSS-2 | 38.10 | 25.40 | 25.40 | 14.63 | 101.70 | 106.20 | 33.20 | 6.0/4.8 | 48.36 | 168.00 | 13.40 | |

28BSS-2 | 44.45 | 27.94 | 30.99 | 15.90 | 124.60 | 129.10 | 36.70 | 7.5/6.0 | 59.56 | 216.00 | 16.60 | |

32BSS-2 | 50.80 | 29.21 | 30.99 | 17.81 | 124.60 | 129.60 | 42.00 | 7.0/6.0 | 58.55 | 270.00 | 21.00 | |

40BSS-2 | 63.50 | 39.37 | 38.10 | 22.89 | 154.50 | 160.50 | 52.96 | 8.5/8.0 | 72.29 | 378.00 | 32.00 | |

48BSS-2 | 76.20 | 48.26 | 45.72 | 29.24 | 190.40 | 198.20 | 63.80 | 12.0/10.0 | 91.21 | 600.00 | 50.00 | |

Triplex Chain

ZMIE Chain No. | Pitch | Roller Diameter | Width Between Inner Plates | Pin Diameter | Pin Length | Inner Plate Depth | Plate Thickness | Transverse Pintch | Ultimate Tensile Strength | Weight Per Meter | ||

P | d1 max | b1 min | d2 max | L max | Lc max | h2 max | T max | Pt | Q min | q |

||

mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | kg/m |

||

04CSS-3 | 25SS-3 | 6.35 | 3.30 | 3.18 | 2.31 | 21.00 | 21.50 | 6.00 | 0.80 | 6.40 | 6.30 | 0.44 |

06CSS-3 | 35SS-3 | 9.525 | 5.08 | 4.77 | 3.58 | 32.70 | 33.50 | 9.00 | 1.30 | 10.13 | 14.22 | 1.05 |

08ASS-3 | 40SS-3 | 12.70 | 7.95 | 7.85 | 3.96 | 45.40 | 46.60 | 12.00 | 1.50 | 14.38 | 25.38 | 1.90 |

10ASS-3 | 50SS-3 | 15.875 | 10.16 | 9.40 | 5.08 | 57.00 | 58.50 | 15.09 | 2.03 | 18.11 | 39.96 | 3.09 |

12ASS-3 | 60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.50 | 73.30 | 18.00 | 2.42 | 22.78 | 57.24 | 4.54 |

16ASS-3 | 80SS-3 | 25.40 | 15.88 | 15.75 | 7.92 | 91.70 | 93.60 | 24.00 | 3.25 | 29.29 | 102.06 | 7.89 |

20ASS-3 | 100SS-3 | 31.75 | 19.05 | 18.90 | 9.53 | 112.20 | 116.30 | 30.00 | 4.00 | 35.76 | 159.30 | 11.77 |

24ASS-3 | 120SS-3 | 38.10 | 22.23 | 25.22 | 11.10 | 141.40 | 145.20 | 35.70 | 4.80 | 45.44 | 228.60 | 17.53 |

28ASS-3 | 140SS-3 | 44.45 | 25.40 | 25.22 | 12.70 | 152.20 | 156.80 | 41.00 | 5.60 | 48.87 | 342.72 | 22.20 |

32ASS-3 | 160SS-3 | 50.80 | 28.58 | 31.55 | 14.27 | 181.80 | 186.60 | 47.80 | 6.40 | 58.55 | 408.24 | 30.02 |

36ASS-3 | 180SS-3 | 57.15 | 35.71 | 35.48 | 17.46 | 204.40 | 210.20 | 53.60 | 7.20 | 65.84 | 504.42 | 38.22 |

40ASS-3 | 200SS-3 | 63.50 | 39.68 | 37.85 | 19.85 | 223.50 | 230.40 | 60.00 | 8.00 | 71.55 | 636.84 | 49.03 |

48ASS-3 | 240SS-3 | 76.20 | 47.63 | 47.35 | 23.81 | 271.30 | 278.60 | 72.39 | 9.50 | 87.83 | 918.54 | 71.60 |

05BSS-3 | 8.00 | 5.00 | 3.00 | 2.31 | 19.50 | 20.20 | 7.10 | 0.80 | 5.64 | 6.66 | 0.48 | |

06BSS-3 | 9.525 | 6.35 | 5.72 | 3.28 | 33.50 | 34.60 | 8.20 | 1.30 | 10.24 | 14.94 | 1.16 | |

08BSS-3 | 12.70 | 8.51 | 7.75 | 4.45 | 45.10 | 46.10 | 11.80 | 1.60 | 13.92 | 28.50 | 2.03 | |

10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.70 | 54.10 | 14.70 | 1.70 | 16.59 | 40.02 | 2.77 | |

12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.50 | 63.10 | 16.00 | 1.85 | 19.46 | 52.02 | 3.46 | |

16BSS-3 | 25.40 | 15.88 | 17.02 | 8.28 | 99.80 | 101.20 | 21.00 | 4.15/3.1 | 31.88 | 96.00 | 8.13 | |

20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.20 | 117.90 | 26.40 | 4.5/3.5 | 36.45 | 150.00 | 10.82 | |

24BSS-3 | 38.10 | 25.40 | 25.40 | 14.63 | 150.10 | 154.60 | 33.20 | 6.0/4.8 | 48.36 | 255.00 | 20.10 | |

28BSS-3 | 44.45 | 27.94 | 30.99 | 15.90 | 184.20 | 188.70 | 36.70 | 7.5/6.0 | 59.56 | 318.00 | 24.92 | |

32BSS-3 | 50.80 | 29.21 | 30.99 | 17.81 | 183.20 | 188.20 | 42.00 | 7.0/6.0 | 58.55 | 402.00 | 31.56 | |

40BSS-3 | 63.50 | 39.37 | 38.10 | 22.89 | 226.80 | 233.80 | 52.96 | 8.5/8.0 | 72.29 | 570.00 | 48.10 | |

48BSS-3 | 76.20 | 48.26 | 45.72 | 29.24 | 281.60 | 289.40 | 63.80 | 12.0/10.0 | 91.21 | 900.00 | 75.00 | |

Stainless steel roller chain is the most common and widely used corrosion resistant roller chain in the world. This is due to the highly anti-corrosive properties of stainless steel, as well as the extremely broad range of temperatures and applications that stainless steel chains can operate in. ZMIE stainless steel roller chain is made from high grade materials. These perform extremely well in environments that are acidic, alkaline, where direct contact with food is a consideration, where the chain will be exposed to water, and for very high or very low temperature locations where resistance to corrosion is a requirement. ZMIE stainless steel roller chain all components made from austenitic rust-proof steel, the chains are prestretched to 30 % of breaking load and chain’s tensile strength is approximately 65% that of standard carbon steel chain.