How to Judge the Quality of the Conveyor Chain?

time2021/11/06

- The quality of the conveyor chain is related to the efficiency of the operation, and it is difficult to judge by only the surface inspection.

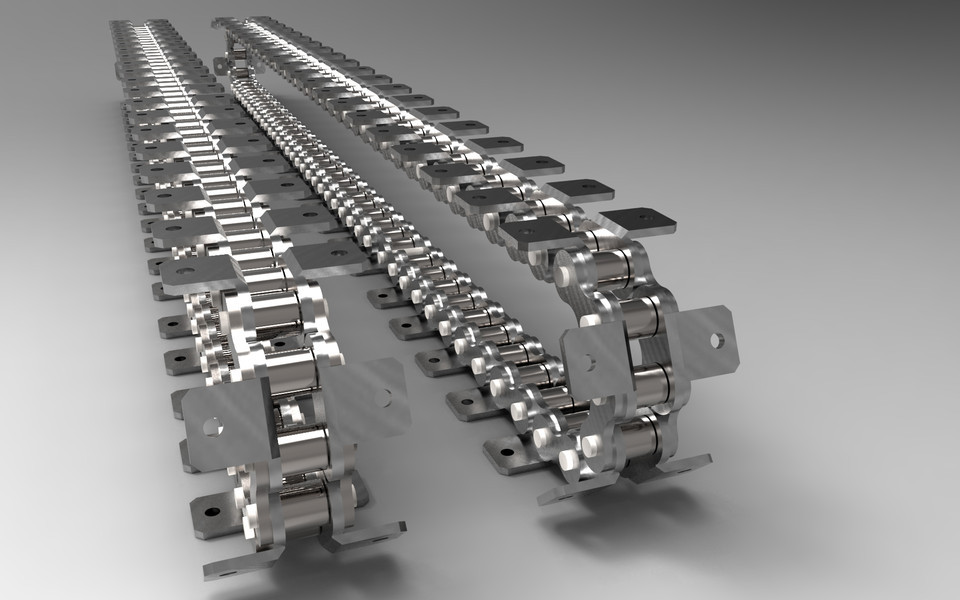

The chain is generally a metal link or ring, which is mostly used for mechanical transmission. The chain includes four series of transmission chains, conveyor chains, drag chains, and special professional chains. The flexible system composed of rigid components makes it a mechanical basic part with a wide range of uses. As the most widely used chain in the industry, the quality of the conveyor chain is directly related to the operating efficiency. If the chain is worn out, we can check it in time to avoid the loss to the greatest extent.

Generally, we judge the quality of the conveyor chain mainly from the appearance, accuracy, elongation, and other aspects of the following chains.

Visual inspection of the chain

(1) Whether the inner/outer chain piece is deformed, cracked, or embroidered.

(2) Whether the pin is deformed or rotated or is embroidered.

(3) Whether the roller is cracked, damaged, or excessively worn.

(4) Whether the joint is loose and deformed.

(5) Whether there is abnormal noise or abnormal vibration during operation, and whether the chain lubrication is in good condition.

The accuracy of the chain should be measured according to the following requirements

(1) The conveyor chain manufacturer has cleaned the chain before measurement.

(2) Enclose the tested chain on the two sprockets, and the upper and lower sides of the tested chain should be supported.

(3) The chain before measurement should stay for 1 min under the condition of applying one-third of the minimum ultimate tensile load.

(4) When measuring, apply the specified measuring load on the chain to make the upper and lower chains tense. The chain and the sprocket should ensure normal meshing.

(5) Measure the center distance between the two sprockets.

Measuring chain elongation

(1) In order to remove the clearance of the entire chain, it is necessary to measure under a certain degree of pulling tension on the chain.

(2) When measuring, in order to minimize the error, measure at 6-10 knots (link).

(3) Measure the inner L1 and outer L2 dimensions between the rollers of the number of pitches to obtain the judgment dimension L=(L1+L2)/2.

(4) Calculate the elongation length of the chain. This value is compared with the use limit value of the chain elongation in the preceding paragraph.

(5) Chain elongation=judgment size-reference length/reference length*100%.

(6) Reference length = chain pitch * number of sections.

The quality of the conveyor chain is often difficult to judge on the surface. Only after in-depth inspection can the accuracy of the parts or the hardening depth of the induction parts be known. We can use the above methods to judge the quality of the conveyor chain or check the wear of the conveyor chain. If the conveyor chain is severely worn, we must replace the chain in time.

If you want to know more about the conveyor chain after reviewing the above, you can contact ZMIE for professional advice and solutions.

As a quality chain supplier with rich experience, ZMIE has become a leader in this industry with excellent manufacturing technology and thoughtful service. We have a professional production team and a strict quality inspection system, which can control the quality of our products in an all-round way. We can also provide thoughtful one-stop service and professional solution technology according to the needs of users. If you are interested in our products, you can send us your needs directly, and we will provide you with a satisfactory answer!