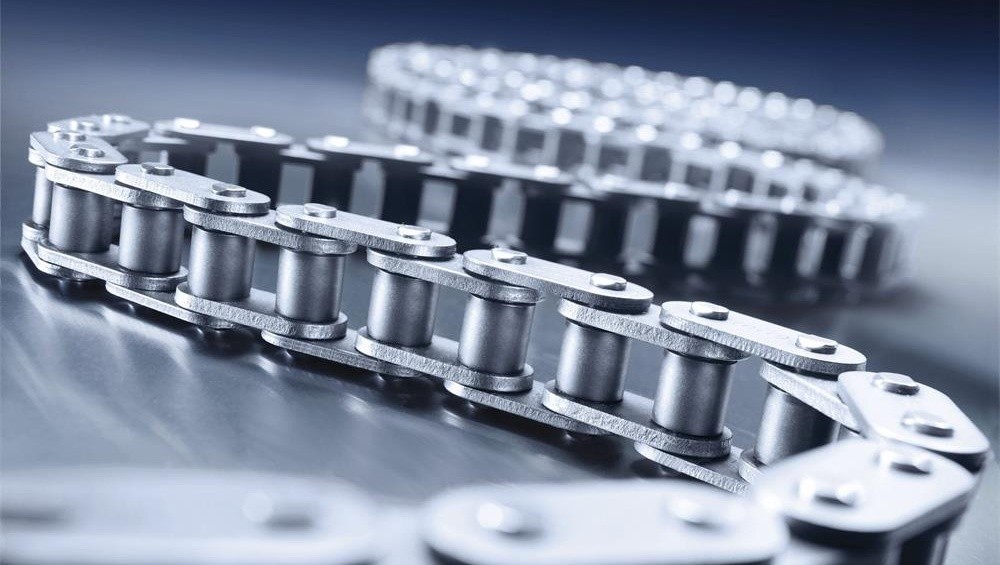

Common Faults and Maintenance Methods of Roller Chains

time2021/06/25

- When the roller chain is loose or the load is too large, it will cause some failures in the chain.

A roller chain is a very widely used chain drive, but when the chain has some failures, it will lead to operating abnormally. At this time, we need to repair and deal with different fault points. The following are the common faults and repair methods of roller chains.

Sprocket tooth wear

If there is obvious wear on both sides of the sprocket teeth, the transmission alignment is not good. If there is a "curved groove", it means that the sprocket should be replaced with excessive wear. You can also install the sprocket backward so that the lighter wear side faces the chain. It is best to replace the excessively worn sprockets together with the chain.

Pin wear

Usually, pin wear is caused by insufficient lubrication. Always check whether there is an abrasive in the lubricating oil or change the lubrication method.

Chain plate side grinding

If the inner surface of the inner link plate is severely worn, it means that the transmission is not aligned. The solution is to check the alignment of the shaft and the sprocket. If there is no problem with the installation, you can observe whether the rigidity is insufficient due to excessive load and deformation during operation.

Chain jitter

The reason for the jitter of the roller chain is that the chain is too loose, the load is too large, or one or more chain links are not flexible. The solution is to install a chain tensioner or an adjustable center distance. Reduce the load if possible.

The chain does not fit well with the sprocket

If the chain and the sprocket do not fit well, it may be that the chain hinge is worn and the pitch is elongated. If there is a phenomenon of tooth skipping, the chain should be replaced in time. If the sprocket is worn out, replace it to avoid damage to the new chain.

Excessive chain running noise

The cause of excessive noise is that the sprocket is not coplanar; the chain tension is too large or too small; the lubrication is insufficient; the chain and the sprocket are worn, or the chain pitch is too large. The solution is to check the coplanarity of the front and rear axles parallel to the sprocket and correct them. Adjust the center distance and tensioning device to obtain proper tightness and ensure lubrication to the workpiece.

Before and after using the roller chain, we need to check and lubricate frequently to prevent the roller chain from premature wear due to the above failures, thereby shortening the service life. If you want to know more about roller chains after reading the above, you can contact us for more detailed solutions.

As a professional quality chain supplier, we have always been committed to providing customers with high-quality and safe products. We have a professional production team and a strict quality management system, which can control the quality of our products in an all-round way. At the same time, we can also provide thoughtful services and effective solutions according to customer needs. If you want to buy our roller chain, please contact us immediately!