Inspection and Maintenance of Conveyor Chain

time2021/04/12

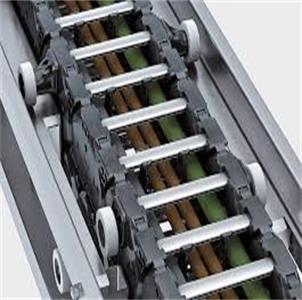

- The conveyor chain is easy to be damaged after long-term use, and we need to conduct regular inspection and maintenance. Let's talk about methods of inspecting and maintaining conveyor chains.

We need to check the conveyor chain in time and find faults and repair or replace them in time to avoid larger faults. So the following are some methods of inspection and maintenance.

The method of inspection

1. Check the main transmission parts of the conveyor line, such as whether the chain sprocket, tensioning device, chain buckle is loose, shifted, or disconnected, whether the chain plate is bent or recessed, if necessary, adjust it in time, return it to the position, and tighten it.

2.Check the head motor, tooth box, and all supporting special machines for any loose or abnormal conditions, and deal with them in time if found.

3. Check the components in the electric control box, the travel switch, the electric eye, and its feet to see if there is any looseness or deviation and whether the conductive wheel is skewed or damaged. If found, correct it in time.

4. Check whether the various moving components are strong, stable, and the response time is normal, whether there is obvious noise, abnormal sound, and vibration, whether the pneumatic components and pipelines are leaking or loose, and modify them.

5. Check whether the rails are bent or deformed, whether the connecting screws of the armrest brackets and other components are loose, whether the chain is loose, adjust and maintain it in time.

6. Check the chain tension of the conveyor line. If it is too loose, adjust the chain tension device at the end of the machine to ensure that the chain tension is appropriate.

The method of maintenance

1. The tightness of the stainless steel conveyor chain should not be too tight or too loose, as this will damage the conveyor chain.

2. The stainless steel conveyor chain should be kept clean to avoid sunlight and rain, and prevent contact with acid, alkali, organic solvents, and other substances.

3. If the conveyor chain is severely worn, it should be replaced with a new conveyor chain and other parts to ensure good results and prolong its life.

4. Lubricating oil should be added to the chain in time when the chain is working, which can make the chain work more smoothly and quickly, and reduce wear.

5. The old conveyor chain cannot be mixed with the new conveyor chain. This will cause impact and damage the conveyor chain.

6.The time on the conveyor chain is not used there, then it can be cleaned with diesel or kerosene, then coated with engine oil, and placed in a dry place.

Timely inspection and regular maintenance can extend the life of the standard conveyor chain and avoid more failures.

We are a professional quality chain supplier with 20 years of experience in this area. We focus on producing high-quality chains and sprockets, If you want to know the corresponding customized services and solutions, please contact us immediately!